TECO Showcases Robotic Joint Modules and Drone Motors as Highlights at 2025 Automation Taipei

The 2025 Automation Taipei Exhibition officially kicked off today (20th), with TECO Electric & Machinery Co., Ltd. (1504) presenting its theme of “Smart and Low-Carbon Manufacturing for Sustainable and Intelligent Environment.” The company is spotlighting advanced solutions in key process control and smart, high-efficiency drive applications. Beyond demonstrating comprehensive applications of “smart manufacturing” and “low-carbon factories,” TECO is presenting multi-legged robotic joint modules, high-efficiency drone motors, and overhead hoist transport (OHT) systems designed for the semiconductor industry.

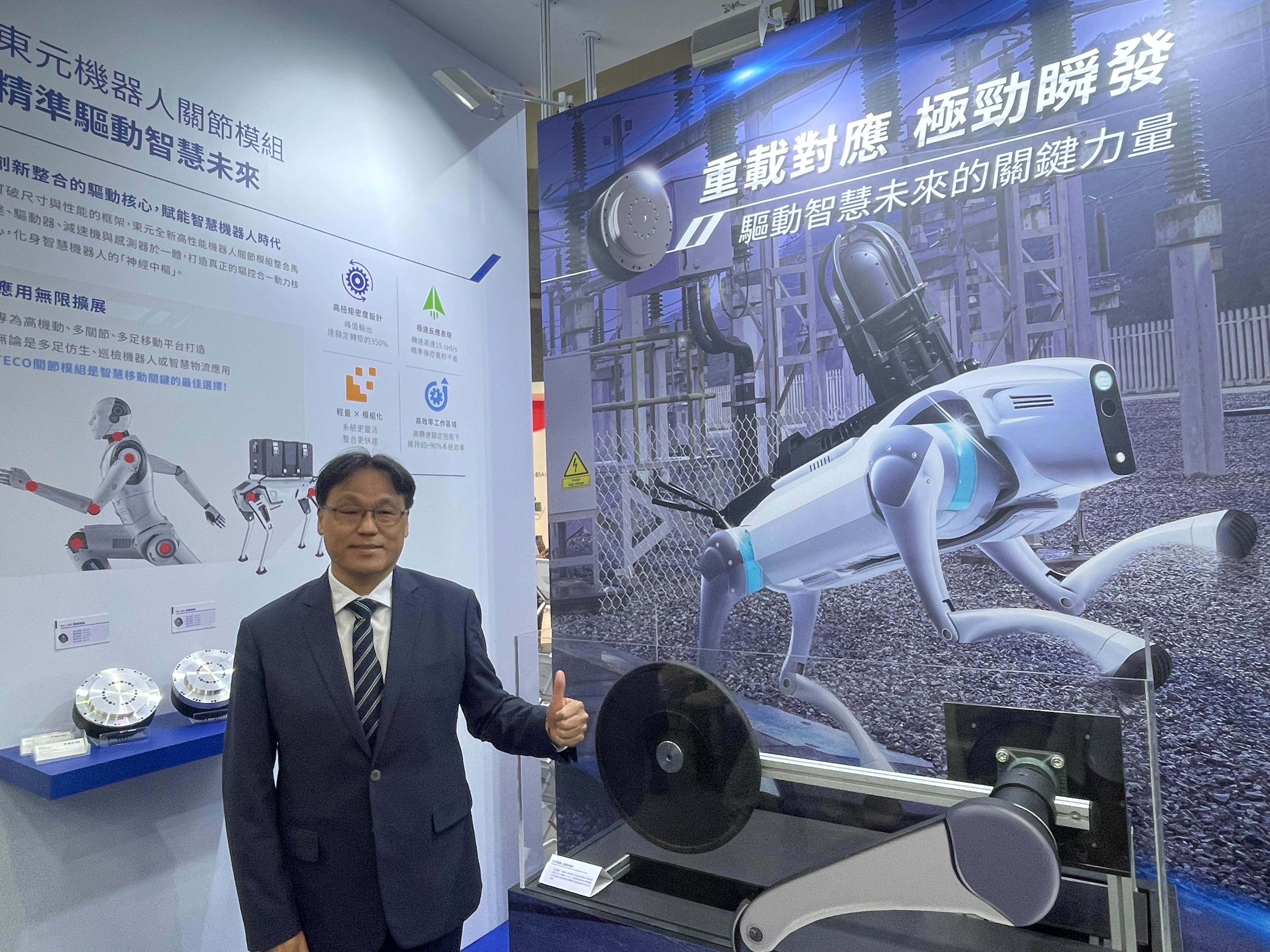

TECO President Fei-Yuan Kao emphasized that TECO is committed to supporting business in transformation and upgrading—from process automation, smart mechatronics, unmanned vehicles, to energy-saving solutions—enabling green and sustainable manufacturing environments. These solutions aim to deliver higher efficiency, stability, and intelligence, in line with TECO’s vision: The key driver in realizing global electrification, intelligence, and green energy.

Robotic Joint Modules: Lightweight and High-Performance for Smart Motion

Robots are increasingly indispensable in smart manufacturing fields such as industrial inspection, intelligent logistics, and even firefighting and rescue. TECO’s robotic joint modules feature an all-in-one design, integrating a reducer, servo drive, and high-precision sensors into a compact unit. With lightweight design, high torque density, and modular scalability, the modules provide exceptional flexibility. At the 2025 exhibition, TECO showcased products with a peak output torque of up to 360 Nm—350% of the rated torque—with speeds reaching 15 rad/s, outperforming mainstream competitors in the market. At the same torque output (140 Nm), TECO’s joint modules sustain peak performance longer than comparable products, ensuring more stable and efficient robotic operations.

TECO Motors Powertrain System Powering Innovation in Drones and Unmanned Vehicles

Another major highlight is TECO’s high-efficiency drone motors, designed for multi-rotor UAVs in the 1–20 kg class. These motors are optimized for applications such as agricultural spraying, aerial mapping, and industrial inspection, delivering stable flight, extended endurance, and strong payload capacity. Built with a high-efficiency winding design and optimized magnetic circuit, TECO’s drone motors offer lightweight structure, high thrust-to-weight ratio, strong torque, and low heat generation—making them a highly reliable power solution for small to mid-sized UAVs.

From Process Automation to Energy Efficiency: Driving Low-Carbon Upgrades

In a semiconductor factory scenario, TECO showcases its OHT (Overhead Hoist Transport) equipped with a DC servo system and miniaturized drive unit that is 75% smaller than conventional AC servo drives. With integrated communication design, the system can increase production space efficiency by 40%, while supporting warehouse tracking and storage optimization—helping customers achieve fully upgraded smart production lines.

TECO also introduces the next-generation JSDG3 high-performance AC servo system, which reduces positioning time and ensures process stability in high-precision applications such as CNC machine tools and copper foil slitting. Its stepper motor series, with high precision and fast response, is suited for AOI inspection and high-frequency start-stop processes. Co-showcasing with Yaskawa Electric, TECO is presenting the MP3100 motion control module and the Σ-7S FT servo drive, delivering deviation-free and multi-axis synchronized control. TECO’s affiliate YATEC Engineering is also exhibiting roll-to-roll process and energy-saving control solutions for thin film, copper foil, and e-paper production lines, providing highly accurate tension error control (±0.5–2%) for improved precision and stability.

Comprehensive “Smart Manufacturing” and “Low-Carbon Factory” Solutions

For energy-intensive industries, TECO is showcasing medium- and high-voltage variable-frequency energy-saving systems, integrated with energy management platforms, to help sectors such as steel, petrochemicals, and paper reduce carbon emissions while improving efficiency. The exhibition also features a complete portfolio of power and equipment efficiency solutions, including:

· Transformers for enhanced power quality

· Hairpin industrial motors with 70% higher power density

· Permanent-magnet direct-drive cooling tower systems achieving up to 40% energy savings

· Hybrid solar-powered variable-frequency air conditioning systems

Through these innovations, TECO demonstrates its comprehensive capabilities in advancing smart manufacturing and accelerating low-carbon transformation.