Driving Energy Efficiency and Achieving Smart Energy Management

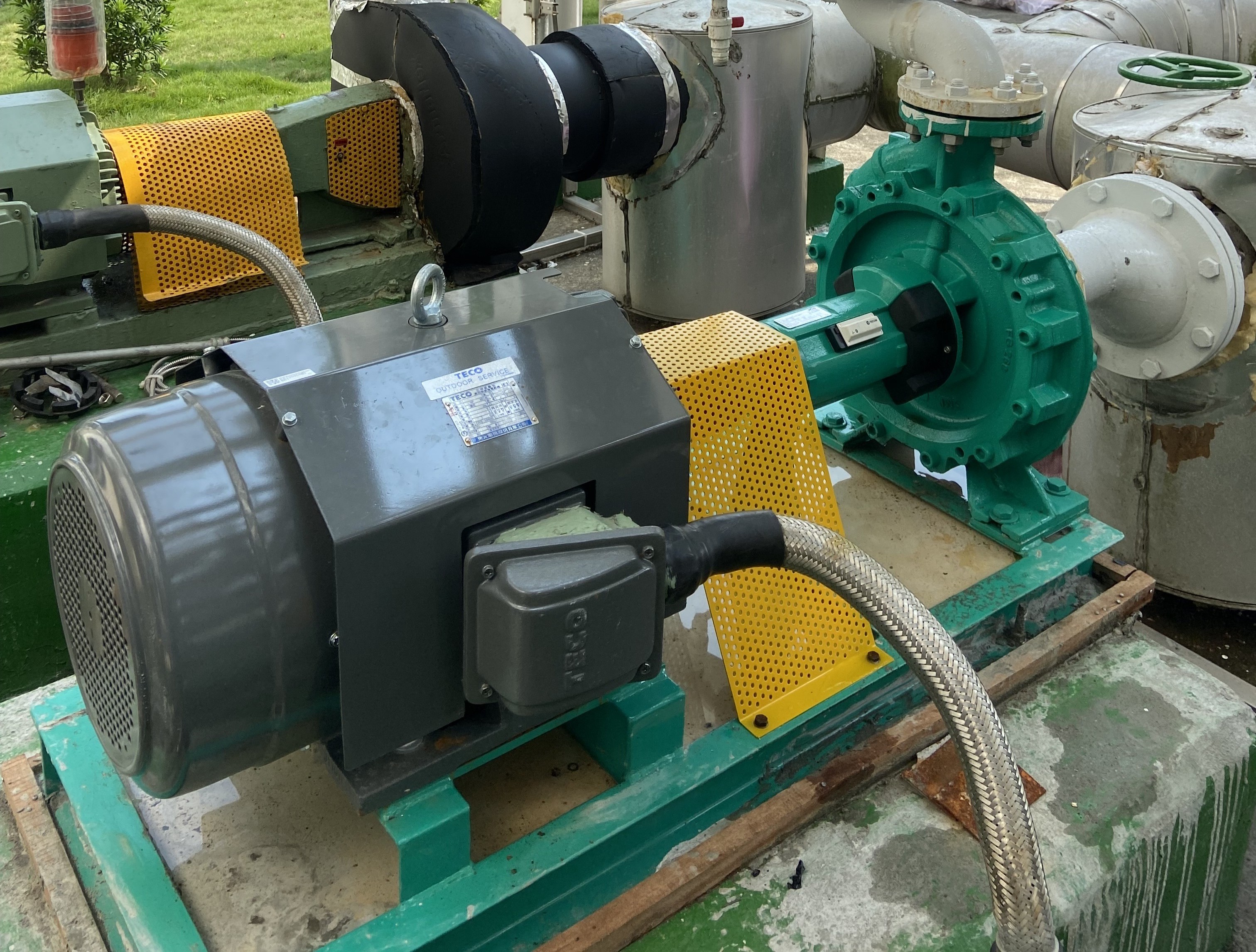

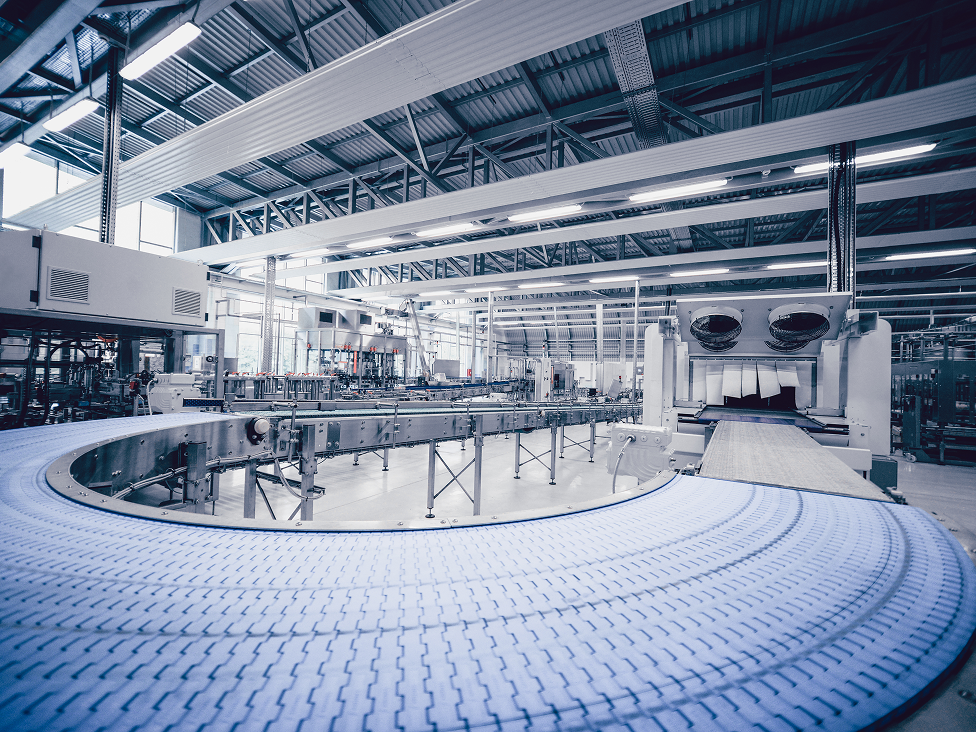

TECO’s smart energy-saving control and energy management technologies provide comprehensive energy-saving solutions for power equipment and utility systems, helping enterprises significantly enhance energy efficiency and advance toward intelligent low-carbon transformation. Through intelligent control and AI-driven data analytics, the system automatically adjusts equipment output—such as maintaining constant temperature, constant pressure, or fixed flow—based on actual load demand, achieving an average energy-saving rate of over 40%.

We integrate a wide range of sensing devices, including smart meters, pressure sensors, flow sensors, and temperature/humidity sensors, enabling real-time collection of energy consumption and equipment operating data. All information is consolidated on a visualized management platform, where intuitive dashboards clearly present energy usage, savings performance, and carbon-reduction results—effectively improving management and decision-making efficiency.

In addition, the platform is highly flexible, supporting multiple communication protocols and sensing devices, making it suitable for factories, buildings, campuses, and smart industrial parks. The system can also execute precise control of energy-intensive equipment based on carbon-reduction methodologies, enabling deep energy savings while meeting carbon inventory and carbon-reduction verification requirements.

From energy monitoring and equipment management to environmental monitoring and cross-system integration, TECO’s smart energy-saving solution adopts a modular design to meet the needs of various industries, helping enterprises build more efficient, intelligent, and sustainable operations.

Core Advantages

One-Stop Energy-Saving Services

Integrated system solutions that help enterprises achieve their energy-saving goals.

Diverse Energy-Saving Needs

Cross-domain resource integration to flexibly meet various site requirements.

Customized Energy-Saving Solutions

Professional team conducts on-site evaluations and designs optimal energy-saving configurations.

Smart Energy Monitoring

Transparent equipment energy usage to prevent abnormal consumption risks.

Projects

Subsystems / Modules

Products

Applications

Contact Us

Joy Chen

Taiwan Sales

- joy1002@teco.com.tw

- +886-2-6615-9111 #1327

Kevin Chang

Energy Saving Solutions

- kevinyt@teco.com.tw

- +886-2-6615-9111 #1680

Pablo Huang

Overseas sales

- pablo.huang@teco.com.tw

- +886-2-6615-9111 #1798