Wuxi fully automated stamping center, an embodiment of "energy conservation, discharge emission, smart application, and automation," was inaugurated

Wuxi Fully Automated Stamping Center Goes Live

[Released: 2016-11-11]

TECO Electric & Machinery has invested in Wuxi, Jiangsu, PRC, to build a fully automated plant dedicated to high-efficiency motor components—stator and rotor lamination stamping. The intelligent production center officially opened on the 11th. It is also

a green factory powered in part by renewable energy and has obtained LEED Gold green building certification—the first of its kind in the industry. Chair Sophia Chiu noted that under TECO’s “energy saving, emissions reduction, intelligence, automation” strategy,

many of the company’s successful products—such as smart motors and the MES system—are deployed extensively in the stamping center, showcasing TECO’s progress and ambition in intelligent automation.

Building a Global Parts Supply Hub with Centralized Production & Management

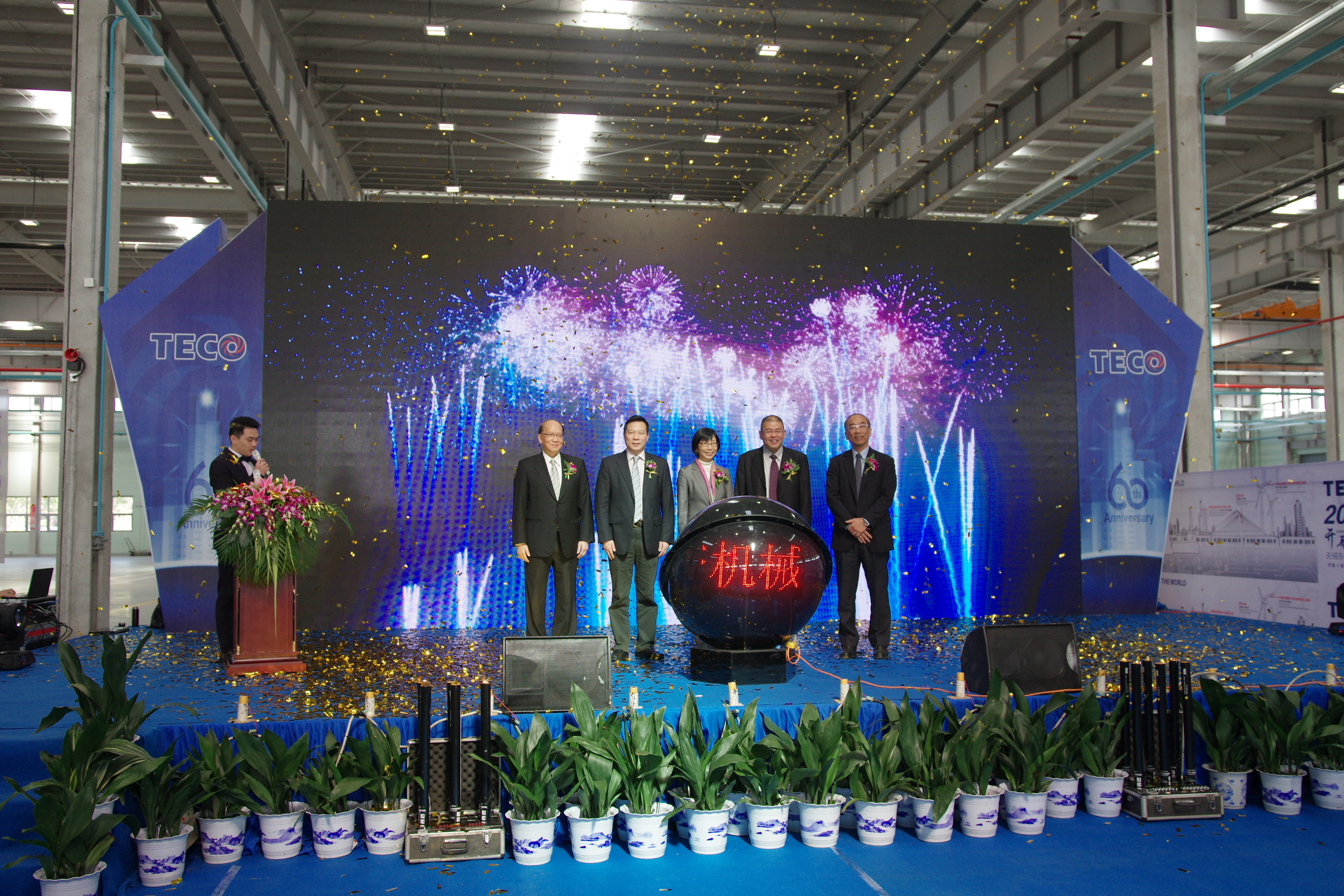

Chair Sophia Chiu and TECO Group Vice Chairman Andrew Liu attended the opening ceremony in Wuxi, while Group Chairman Theodore Huang sent a video message expressing delight that the long-planned global parts supply hub is now complete, paving the way for

faster development ahead. Chair Chiu outlined the project’s rapid, smooth milestones: land tender completed in Nov 2015, contract signed in Dec 2015, groundbreaking on 2016/01/12, plant completion and acceptance on 10/15, and grand opening on 11/11. Going

forward, the Wuxi Stamping Center will serve not only the mainland China market but become a global supply center, enabling a centralized production and management model across TECO Group and driving overall efficiency and revenue growth.

Fully Automated Base: Annual Output of 1 Million Stators and 1 Million Rotors

With mass production now underway, the Wuxi center is expected to produce 1,000,000 stator laminations and 1,000,000 rotor laminations annually, with capacity expansions planned based on market demand. In TECO’s 60th anniversary year, Chair Chiu emphasized

how the precision stamping center embodies TECO’s four management pillars:

Energy saving & emissions reduction: reflected in the LEED Gold certified facility.

Automation: evidenced by TECO’s investment in world-class, advanced automated production equipment.

Intelligence: realized through extensive IoT adoption for smart monitoring and management, including paperless dispatch and automated intelligent measurement.

Under this strategy, products such as servo drives and motors, IE3 high-efficiency motors, smart motors, ground-source heat pumps, and the MES are widely utilized in the stamping center. This is TECO’s first fully automated production base, a modern plant

aligned with industry trends that enables effective cost reduction and control.

Green Power & Energy Recovery: LEED Gold Certified

Since launching the “TECO GO ECO” initiative in 2008, TECO has focused on products that save energy and reduce emissions. The Wuxi stamping center fully implements green energy and renewable strategies: plantwide TECO high-efficiency motors, process waste-heat

recovery, ground-source heat-pump HVAC, and rainwater harvesting, achieving both conservation and reuse. On the supply side, photovoltaic solar and TECO-built wind power systems provide approximately 70,000 kWh of green electricity per year, used for employee

EV charging and plant lighting.

US$80 Million Phase-1 Investment; Phases II & III to Follow

Wuxi TECO Precision Co., Ltd. is a wholly owned subsidiary of TECO Group, occupying about 53,336 m². The stamping center inaugurated on the 11th is Phase I, with an investment of roughly US$80 million. Phases II and III are planned to continue the build-out.