Brief introduction to IoT Applications

TECO joins hands with affiliates Yatec Engineering, Tecom, and Information Technology Total Service in R&D on cloud-end energy-conserving products and systems, including construction of IoT-based convenient, safe, and high-performance production lines, in line with the trend of Industry 4.0. TECO has constructed smart production line in the Chungli factory in Taoyuan and plans to standardize the experience in helping factories of small and medium enterprises embrace Industry 4.0.

Meanwhile, TECO's home appliances division has also been actively developing IoT services and has cooperated with municipal governments and schools in optimizing air quality, forging optimal cozy and healthy interior space for consumers.

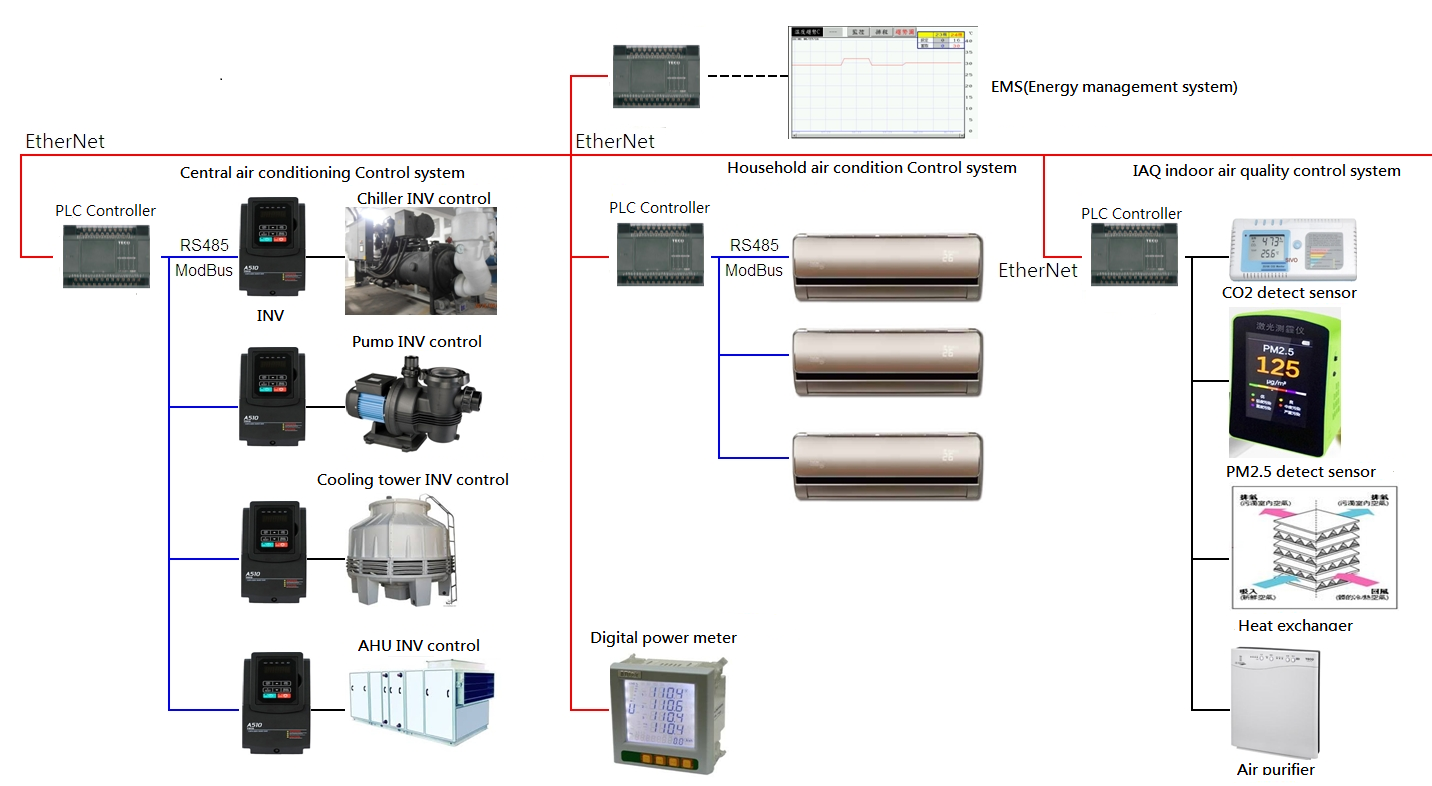

Energy management system

EMS aims to optimize power deployment, achieving optimal energy utilization via balancing power consumption in peak and off hours, via around-the-clock real-time monitoring of the operating status of the power equipment and motors in communities, capable of preventing malfunctions without alarm (such as elevator, water-pumping equipment, and variable-frequency air conditioner).

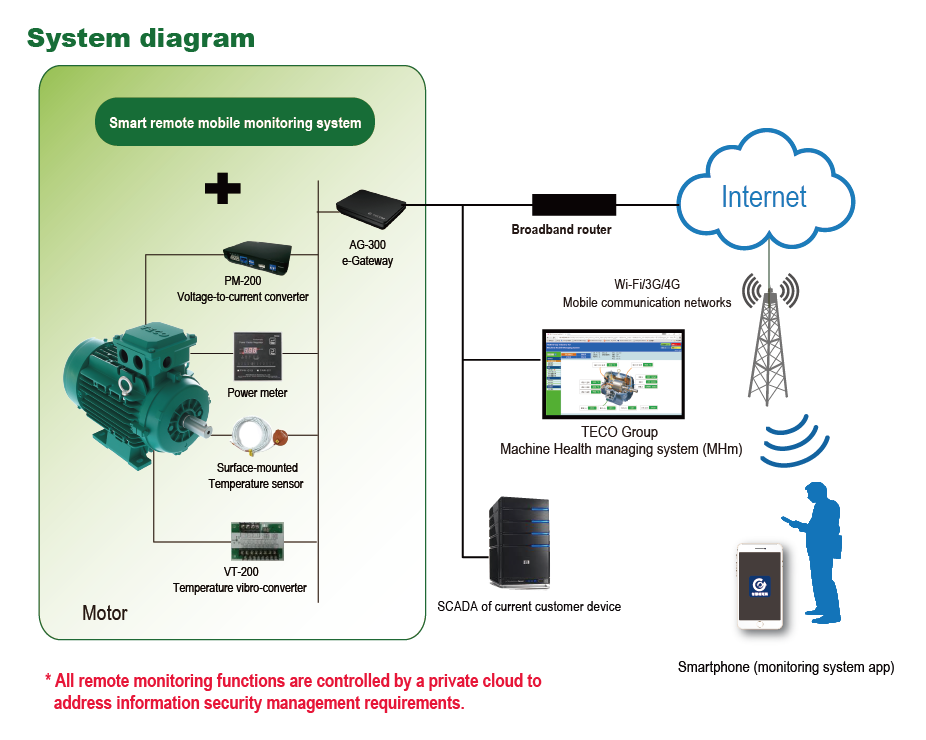

Electromechanical health management system

TECO's latest remote mobile monitoring device can be installed on electromechanical equipment for reading and retrieving major operational information for transmission to platform-management mechanism, providing operating information, alarming, diagnosing irregular trend, conducting preventive maintenance, recording power consumption, setting equipment parameter, and designating parameter setting, all unprecedented functions.

Energy-conserving smart air-quality monitoring service

Install sensors with cloud-end connection for automatic monitoring of temperature, humidity, CO2 density, and PM2.5 index, plus connection with exhaust fans and air conditioners for automatic adjustment and control, thereby keeping optimal air quality for interior space.