EU Taxonomy

In 2024, TECO applied EU Taxonomy-Eligible criteria to classify sustainability-related revenue and investments. The company disclosed detailed breakdowns of taxonomy-eligible business segments across three main business groups, achieving 52.0% sustainable revenue ratio, 13.5% CAPEX, and 15.6% OPEX allocation.

Future Business Opportunities in Climate Change

Electrification

Green Energy

Product Lifecycle Management

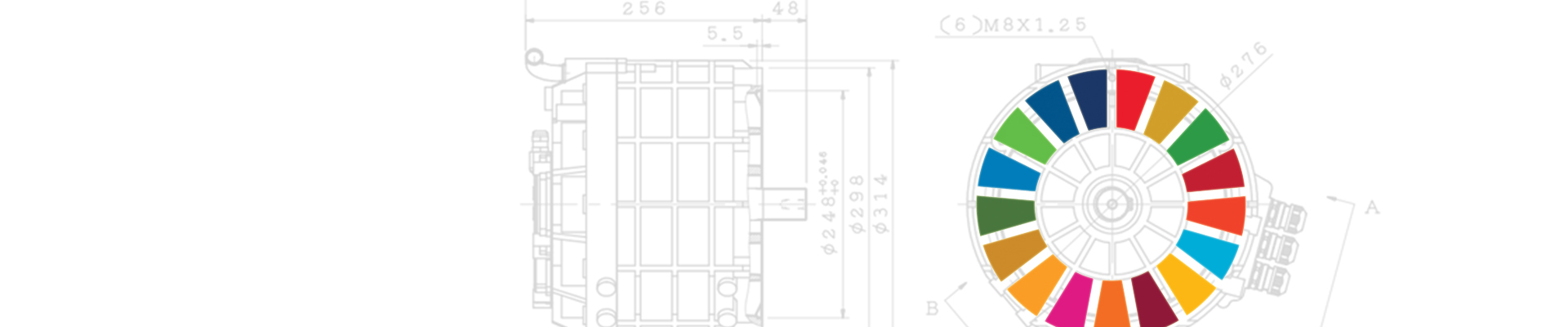

TECO implements lifecycle-based sustainability strategies from recycling to end-of-life. In 2024, the company enhanced lightweight motor design with T-HiPro+ models, reducing motor weight by 28.6% and associated emissions by 27,532 kg per unit. Silicon steel scrap and metal components reached an 82.3% recycling rate for motor housings, and 87.2% of paints used were water-based, cutting VOC emissions by 4,568.33 kg. Over 99.65% of residential air conditioners adopted ecofriendly refrigerants. Product design is supported by robust internal audits, ensuring safety and regulatory compliance. TECO's recycling ecosystem achieved 96.5% reuse of foundry scrap, while post-use appliances and motors are dismantled for metal recovery through joint ventures. These initiatives strengthen circularity and product sustainability.

1. Calculation of recyclable ratios for sold products:

Estimated total weight of recyclable products (motors + household appliances) sold per year × recyclable material ratio of different product categories (motors 88%, household appliances 52.0%) ÷ Estimated total weight of all products sold per year.

Calculation of estimated total weight of products sold: Due to the large number of sold motor and household product models it is very difficult to create individual weight statistics. Shipped quantity of different product quantities (number of items) × Weight of most frequently sold models is therefore used as the calculation formula for estimated total weight of products sold.

2. Calculation of actual recyclable ratios:

Denominator: Weight of products sold is substituted for weights in the production process which are impossible to trace due to the substantial number of products.

Numerator: Due to different product characteristics, it is difficult to perform actual statistical analysis of recycled quantities. Consequently, the actual recyclable ratio is estimated according to the following scenario, and it is assumed that the products purchased by customers in the respective year are replacements for existing products of the same brand. Assumed recyclable ratios are 100% and 50% for motors and household appliances, respectively.

3. TECO and other home appliance manufacturers have engaged in a joint venture to establish the E&E Recycling Company and assigned directors for the company to provide waste electrical and electronic equipment recycling and processing services. Calculation of benefits derived from recycling: Illustrated by TECO shareholding ratio (13.42%) in E&E Recycling company.

4. Motor product life cycles range from 10–15 years. Since motors are mainly made of metal, the recyclable metal material of one single motor can reach 88%. Consequently, scrapped products are disposed of by customers autonomously through the sale and purchase of valuable metals. TECO has not yet received requests for motor recycling service from customers.

5. Environmental Protection Administration in Taiwan has established the Waste Four Machine Recycle Policy (refrigerator, air conditioner/heater, washing machine, television), and the distribution units that consumers make their purchase from provide the transportation service to the qualified operator for processing; therefore, product manufacturers have a relatively greater difficulty in the actual statistics of the annual recycle amount.

Product Quality Management Plan

Most of TECO’s production sites have obtained ISO 9001 Quality Management System certification, implementing quality control mechanisms throughout all stages from product design, manufacturing, to after-sales service. Through continuous supervision and internal and external audits, the effective operation of the quality management system is ensured, with ongoing improvements in processes and services to enhance customer satisfaction and organizational resilience. Before undergoing external verification, products undergo rigorous internal audits in accordance with internally established quality management and review procedures to ensure compliance with all safety and performance standards.

All TECO products undergo rigorous internal audits based on established quality management and review processes before external validation, ensuring compliance with safety and performance standards. Over the past four years (2021-2024), no recalls due to product defects have occurred, demonstrating TECO’s robust management systems and risk prevention capabilities in product design, production, and quality control, enhancing customer trust and operational resilience.