Raw Material Management Plans

|

Raw Material Management Plans |

2023 Actions |

|---|---|

|

Conducting an assessment to prioritize raw materials |

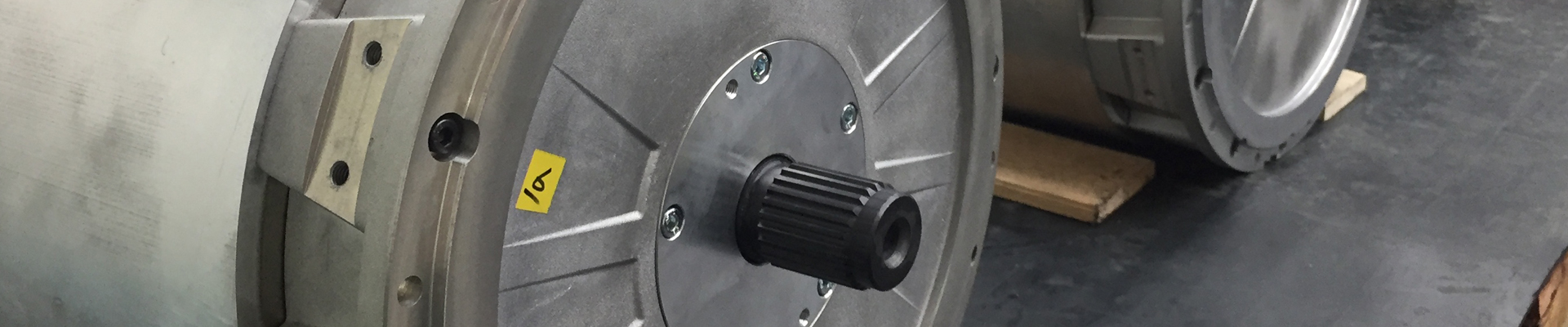

TECO is committed to implementing various sustainable materials management plans. TECO's main sales products are motors. More than 90% of the material components of motors are metal materials. According to product carbon footprint analysis, metal materials and plastic materials are the main impact materials, so they are listed as priority materials. |

|

Traceability of raw materials to their origin |

TECO tracks and traces all purchased materials. In 2023, we conducted a preliminary ecological diversity impact analysis on major steel makers in China, where most of the buying took place. At the same time, we will also further reduce the environmental and social risks generated by raw material suppliers through supplier audits. |

|

Reduction of the negative environmental and social impacts of raw material production |

In the raw material production stage, in order to reduce the negative impact of raw materials on the environment and society, we promise to purchase 100% conflict-free metals. |

|

Setting targets for the share of sustainable raw materials |

No specific target now. TECO will keep implmenting from 2024. |

|

Setting targets for the share of recycled raw materials |

In the design and manufacturing stage, taking the IE3 high-efficiency motor as an example, 86% of the motor is composed of steel and iron. In order to effectively reduce the use of primary steel/iron, we are committed to developing waste resources. Melting silicon steel scraps and reusing them for motor housing, |

|

Reporting progress on sustainable raw materials sourcing targets |

No specific target now. TECO will keep implmenting from 2024. |

|

Training the company’s internal stakeholders on their roles related to sustainable raw materials |

No specific training in 2023. TECO will keep implmenting from 2024. |

The raw materials purchased by TECO globally are steel, iron, copper, aluminum, and a small amount of plastic. Based on regional analysis, the main producing areas are China, Taiwan, Vietnam, and Europe.

Taiwan has a foundry that can melt the scrap generated during the production process in an electric furnace and remanufacturing it into the frame bracket shell required for the motor. Its recycling rate is 22.3% in Taiwan and 4.1% globally.

|

Material |

Origin |

Quantity (ton) |

Recycle Rate |

Notes |

|---|---|---|---|---|

|

Aluminum |

China |

170 |

-- |

Aluminum raw materials are aluminum products and aluminum ingots, and the global purchasing tons in 2023 are regarded as usage. |

|

Taiwan |

460 |

-- |

||

|

Europe |

700 |

-- |

||

|

Copper |

China |

3,670 |

-- |

Copper raw materials are enameled wires, copper bars, and copper pipes (air conditioners). The global purchasing tons in 2023 are considered as usage. |

|

Taiwan |

1,700 |

-- |

||

|

Vietnam |

620 |

-- |

||

|

Iron / Steel |

China |

41,600 |

-- |

The raw materials of steel are silicon steel coils, steel plates, and steel rods. The usage is based on the global purchasing tons in 2023. Taiwan has foundries that can melt scraps and make them into the casings needed for motors. |

|

Taiwan |

15,200 |

3,400 (22.3%) |

||

|

Vietnam |

24,000 |

-- |

||

|

Europe |

1,700 |

-- |

||

|

Plastics |

Taiwan |

60 |

-- |

Mainly used in home appliances. |

In-plant circular

TECO has own foundry in Taiwan, which means we have the ability to melt wastes from production process and re-manufacture it into motor frame bracket housing parts. We have now reached 96.5% of iron reusing rate.

In 2022, the total weight of silicon steel shavings recycled and received: 5,568.8 metric tons. TECO starts to manage recyclable packing materials in one of the factory in Taiwan from 2022, The total weight of non-recyclable materials (plastic, PE, cushioning materials) is 15.95 metric tons; the total weight of recyclable materials (paper, corrugated board, metal) is 7.37 metric tons. Packing recycle management is being expending to all factories in long term.

Lifecycle circular

Industrial motors typically have a design life of 10-15 years, and special designs can extend life up to more than 30 years. At the end of the motor life cycle, the motors are recycled and dismantled by the scrap hardware recycling service companies. 90% of motor total content, including steel, iron, copper and aluminum will be separated and returned to the raw material stage to be remelted and remanufactured. Steel is usually made into angled steel and other building materials that continue to exist in our lives.